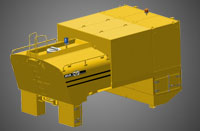

Mega's complete line of fuel and lube truck bodies for rigid and articulated trucks are designed for stable operation, proper weight distribution and long life. Mega service bodies feature an integrated power system which uses fuel supplied directly from the platform fuel tank. The body is fully functional with the truck turned off, saving service meter hours, emissions and fuel consumption. The power system allows complete testing in the factory prior to field installation, minimizing labor cost and chassis integration issues. Every service body includes a complete set of technical manuals detailing installation, operation, maintenance, inspection and replacement parts. Mega bodies are constructed with premium materials and are inspected throughout the manufacturing process to ensure reliability.

Mega fuel and lube truck bodies can be purchased for integration with a dealer-provided truck or as a complete solution with a Mega-provided truck. Purchasing your complete solution directly from Mega streamlines the ordering process and significantly reduces the complexities related to delivery timing and shipping.

The general specifications below reflect nominal capacities for Mega standard configurations. Please contact our Mega Sales Team regarding shipping information and models not listed.

| Fuel | Product Tank 1 |

Product Tank 2 |

Product Tank 3 |

Product Tank 4 |

Used Oil | Coolant | Grease (lb/kg) | |

|---|---|---|---|---|---|---|---|---|

| Gallons | 4,500 | 200 | 200 | 200 | 200 | 200 | 200 | 500 - 1,100 (lb) |

| Liters | 17,000 | 800 | 800 | 800 | 800 | 800 | 800 | 225 - 500 (kg) |

| Fuel | Product Tank 1 |

Product Tank 2 |

Product Tank 3 |

Product Tank 4 |

Used Oil | Coolant | Grease (lb/kg) | |

|---|---|---|---|---|---|---|---|---|

| Gallons | 5,000 | 200 | 200 | 200 | 200 | 200 | 200 | 500 - 1,100 (lb) |

| Liters | 17,000 | 800 | 800 | 800 | 800 | 800 | 800 | 225 - 500 (kg) |

| Fuel | Product Tank 1 |

Product Tank 2 |

Product Tank 3 |

Product Tank 4 |

Used Oil | Coolant | Grease (lb/kg) | |

|---|---|---|---|---|---|---|---|---|

| Gallons | 6,000 | 200 | 200 | 200 | 200 | 200 | 200 | 500 - 1,100 (lb) |

| Liters | 19,000 | 800 | 800 | 800 | 800 | 800 | 800 | 225 - 500 (kg) |

| Fuel | Product Tank 1 |

Product Tank 2 |

Product Tank 3 |

Product Tank 4 |

Product Tank 5 |

Used Oil | Coolant | Grease (lb/kg) | |

|---|---|---|---|---|---|---|---|---|---|

| Gallons | 7,000 | 500 | 500 | 250 | 250 | 250 | 250 | 250 | 500 - 1,100 (lb) |

| Liters | 26,000 | 1,900 | 1,900 | 900 | 900 | 900 | 900 | 900 | 225 - 500 (kg) |

MFL bodies include the following standard features. Feature specifications may vary by model. For additional information, contact our Mega Sales Team.

Our anti-surge baffling provides the most stable, low profile tank on the market today. Mega tank designs focus on safety, performance, and durability to ensure load stability and standard machine handling are maintained. Mega collaborates with the truck manufacturer to match ROPS, braking, and load ratings. This increases chassis life and reduces maintenance costs.

Our anti-surge baffling provides the most stable, low profile tank on the market today. Mega tank designs focus on safety, performance, and durability to ensure load stability and standard machine handling are maintained. Mega collaborates with the truck manufacturer to match ROPS, braking, and load ratings. This increases chassis life and reduces maintenance costs.

The Mega standard air compressor system provides an air tank with water vapor drain, dessicant filter, air dryer and regulator. It also includes a spring-rewind hose reel with threaded hose whip for customer supplied air chucks.

The Mega standard air compressor system provides an air tank with water vapor drain, dessicant filter, air dryer and regulator. It also includes a spring-rewind hose reel with threaded hose whip for customer supplied air chucks.

A mounting provision to relocate the camera from the truck to the service body.

A mounting provision to relocate the camera from the truck to the service body.

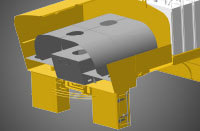

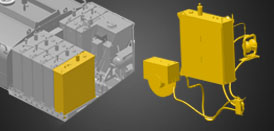

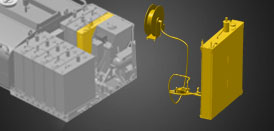

Mega tanks pin directly to the rear pivot mounts of the truck. Line boring the rear pivot mounts ensures accurate direct pin installation of the tank. Mega tanks do not require welding to the frame. New pivot pins and shims are supplied with the tank.

Mega tanks pin directly to the rear pivot mounts of the truck. Line boring the rear pivot mounts ensures accurate direct pin installation of the tank. Mega tanks do not require welding to the frame. New pivot pins and shims are supplied with the tank.

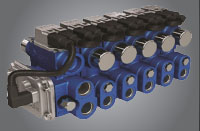

The control valve has a single CAN bus connection and precision software control which reduces wiring and hydraulic connection complexity. The system controls pressure, flow rate, soft start/stop troubleshooting feedback.

The control valve has a single CAN bus connection and precision software control which reduces wiring and hydraulic connection complexity. The system controls pressure, flow rate, soft start/stop troubleshooting feedback.

Mega tanks are abrasive blasted prior to application of anti-corrosive primer. The exterior top coat is color matched to the current manufacturers color.

Mega tanks are abrasive blasted prior to application of anti-corrosive primer. The exterior top coat is color matched to the current manufacturers color.

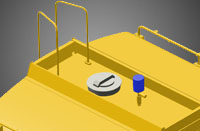

Multiple fall protection, D-ring style tie-off points are welded to the top of tank.

Multiple fall protection, D-ring style tie-off points are welded to the top of tank.

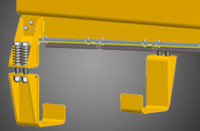

The truck chassis is allowed to flex beneath the spring type front mounting tie downs.

The truck chassis is allowed to flex beneath the spring type front mounting tie downs.

The fuel onload station includes:

The fuel onload station includes:

Note: Receiver is an optional feature.

For safer access to the fill port an anti-skid walkway with steel tread grip is provided.

For safer access to the fill port an anti-skid walkway with steel tread grip is provided.

The fuel pumping station includes:

The fuel pumping station includes:

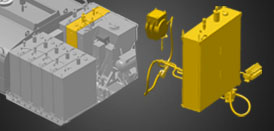

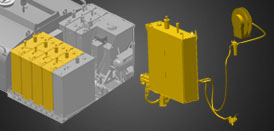

Mega provides a carbon steel grease tank with remote bottom fill or top fill and overflow vent. The tank can be configured to work with HPLV and LPHV delivery systems.

Mega provides a carbon steel grease tank with remote bottom fill or top fill and overflow vent. The tank can be configured to work with HPLV and LPHV delivery systems.

The compact switch pad is located in the cab and includes the following features:

The compact switch pad is located in the cab and includes the following features:

Mega tanks include an access ladder to the top of the tank. Our standard ladder features tread grip rungs for a sure-footed grip and hand rails at the top of the ladder allowing access to the top of the tank.

Mega tanks include an access ladder to the top of the tank. Our standard ladder features tread grip rungs for a sure-footed grip and hand rails at the top of the ladder allowing access to the top of the tank.

Mega tanks include LED lights for long life and low maintenance:

Mega tanks include LED lights for long life and low maintenance:

Mud flaps are standard equipment on available service tanks.

Mud flaps are standard equipment on available service tanks.

Mega's new coolant system includes:

The new oil system includes:

The new oil system includes:

Mega protects your investment by providing a one-year warranty against defects in materials and workmanship. Extended warranties are available for purchase. Visit our Warranty Page for more information.

Mega protects your investment by providing a one-year warranty against defects in materials and workmanship. Extended warranties are available for purchase. Visit our Warranty Page for more information.

Mega's MFL platform structure includes:

The operator station, located at the left rear side of the reel cabinet, includes high and low volume diesel fuel dispensing nozzles, product dispensing nozzles and associated controls. Controls are provided for hose operation, fuel and product pumps, fuel register, integrated power system and LED compartment lighting. The dispensing station is segregated from the inner reel cabinet by a fairlead panel to reduce contamination. The lockable hinge door with door stays provides security and easy access. Benefits and features include:

The rear cabinet enclosure provides ground-level access via a lockable hinged door with door stays to:

The rear cabinet enclosure provides ground-level access via a lockable hinged door with door stays to:

Our stainless steel, safety latch-style tank cover meets DOT 178.345.5 specifications. Breather filters are designed to prevent moisture and contaminants from entering the fuel tank.

Our stainless steel, safety latch-style tank cover meets DOT 178.345.5 specifications. Breather filters are designed to prevent moisture and contaminants from entering the fuel tank.

Mega's reliable technician service screen provides the ability to service your machine with touch screen and video inputs. Features include:

Mega's reliable technician service screen provides the ability to service your machine with touch screen and video inputs. Features include:

Mega provides a complete set of technical manuals detailing installation, operation, maintenance, inspection and replacement parts. Additional manuals are available for purchase. Visit our Technical Manuals Page for more information.

Mega provides a complete set of technical manuals detailing installation, operation, maintenance, inspection and replacement parts. Additional manuals are available for purchase. Visit our Technical Manuals Page for more information.

The used oil system includes:

The used oil system includes:

Your standard MFL bodies can be configured with these optional features. Availability and specifications may vary by model. For additional information, contact our Mega Sales Team.

The additional lighting package provides two additional LED lights on the non-operational side of the tank.

The additional lighting package provides two additional LED lights on the non-operational side of the tank.

Additional sets of manuals are available for purchase. Mega manuals include a complete set of technical manuals detailing installation, operation, maintenance, inspection and replacement parts. Visit our Technical Manuals Page for more information.

Additional sets of manuals are available for purchase. Mega manuals include a complete set of technical manuals detailing installation, operation, maintenance, inspection and replacement parts. Visit our Technical Manuals Page for more information.

Mega offers additional high and low volume dispensing nozzles with swivel for diesel hydraulic hose reels. The high volume nozzle is Wiggins® compatible. The low volume nozzle uses an automotive splash fill style.

Mega offers additional high and low volume dispensing nozzles with swivel for diesel hydraulic hose reels. The high volume nozzle is Wiggins® compatible. The low volume nozzle uses an automotive splash fill style.

Mega offers complete factory installation for all articulated and smaller rigid frame truck models for both customer-supplied and Mega-supplied chassis. Factory installation includes complete commissioning prior to delivery.

Mega offers complete factory installation for all articulated and smaller rigid frame truck models for both customer-supplied and Mega-supplied chassis. Factory installation includes complete commissioning prior to delivery.

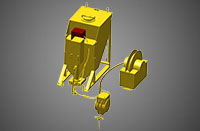

The Mega grease delivery system includes a hydraulically-driven pump and spring-rewind hose reel. Mega offers a high pressure low volume system for zerks and a low pressure high volume system for bulk grease delivery.

The Mega grease delivery system includes a hydraulically-driven pump and spring-rewind hose reel. Mega offers a high pressure low volume system for zerks and a low pressure high volume system for bulk grease delivery.

Mega offers a spring-rewind grounding/bonding reel.

Mega offers a spring-rewind grounding/bonding reel.

Mega offers electro-hydraulic upgrades to the standard, spring-rewind hose reels with hose diameters one inch or larger.

Mega offers electro-hydraulic upgrades to the standard, spring-rewind hose reels with hose diameters one inch or larger.

Mega offers an onload receiver package for diesel fuel which includes a Wiggins® receiver and automatic shutoff feature.

Mega offers an onload receiver package for diesel fuel which includes a Wiggins® receiver and automatic shutoff feature.

The Mega Product Support team offers on-site technical assistance, service advice and training to facilitate installation and reduce field assembly and component repair time.

The Mega Product Support team offers on-site technical assistance, service advice and training to facilitate installation and reduce field assembly and component repair time.

The pressure washer system includes

The pressure washer system includes

Product dispensing guns include anti-drip hose whips. The electronic or mechanical dial meter with resetting totalizer helps dispense precise amounts of products and aids in tracking material usage.

Product dispensing guns include anti-drip hose whips. The electronic or mechanical dial meter with resetting totalizer helps dispense precise amounts of products and aids in tracking material usage.

Mega offers insulated and uninsulated tank enclosures, as well as a heating system for product tanks.

Mega offers insulated and uninsulated tank enclosures, as well as a heating system for product tanks.