Mega manufactures a complete line of water tanks for Komatsu articulated prime movers. These are available for dealer installation or with Mega factory installation. Every tank includes a complete set of technical manuals detailing installation, operation, maintenance, inspection and replacement parts. Mega tanks are constructed with premium materials and are inspected throughout the manufacturing process to produce the best water tanks and spray systems available.

Please contact our Mega Sales Team regarding shipping information and models not listed.

| Mega Model | Nominal Capacity | Prime Mover | Chassis Configuration |

|---|---|---|---|

| MAC6 | 23,000 liters /6,000 gallons | HM300 | Standard Wheelbase |

| MAC6 | 23,000 liters /6,000 gallons | HM300 | Standard Wheelbase Flat Bottom |

| MAC8 | 32,000 liters /8,000 gallons | HM400 | Standard Wheelbase |

MAC tanks include the following standard features. Specifications may vary by model. For additional information, contact our Mega Sales Team.

Mega tanks include an access ladder to the top of the tank. Our standard ladder features tread grip rungs for a sure-footed grip and hand rails at the top of the ladder allowing safe access to the top of the tank.

Mega tanks include an access ladder to the top of the tank. Our standard ladder features tread grip rungs for a sure-footed grip and hand rails at the top of the ladder allowing safe access to the top of the tank.

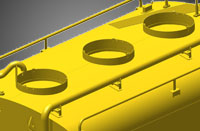

Access ports provide additional access to the interior of the tank beyond the standard access provided through the fill port. This provides multiple points of access to internal tank compartments and includes internal ladder rungs on both sides of tank. Availability varies by model.

Access ports provide additional access to the interior of the tank beyond the standard access provided through the fill port. This provides multiple points of access to internal tank compartments and includes internal ladder rungs on both sides of tank. Availability varies by model.

Larger Mega tanks include banded access manways through the main transverse baffles of the tank.

Larger Mega tanks include banded access manways through the main transverse baffles of the tank.

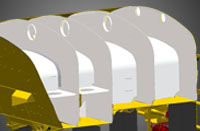

Our anti-surge baffling provides the most stable, low profile tank on the market today. Mega tank designs focus on safety, performance, and durability to ensure load stability and standard machine handling are maintained. Mega collaborates with equipment manufacturers to match ROPS, braking, and chassis load ratings. This increases chassis life and reduces maintenance costs.

Our anti-surge baffling provides the most stable, low profile tank on the market today. Mega tank designs focus on safety, performance, and durability to ensure load stability and standard machine handling are maintained. Mega collaborates with equipment manufacturers to match ROPS, braking, and chassis load ratings. This increases chassis life and reduces maintenance costs.

A camera mounting bracket to relocate the camera from the truck to the water tank.

A camera mounting bracket to relocate the camera from the truck to the water tank.

Mega DiSCS®provides precise application of water spray using CAN bus and logic control technology to operate the spray control system. DiSCS® provides control of all water distribution systems. GPS sensing within DiSCS® automatically regulates the amount of water spray applied relative to vehicle ground speed or distance traveled. This system also provides water pump system protection against operator-induced sudden starts and stops, low water level and overheating due to extended water pump operation. Standard on MAC 7,8,9 and 10 models.

Mega DiSCS®provides precise application of water spray using CAN bus and logic control technology to operate the spray control system. DiSCS® provides control of all water distribution systems. GPS sensing within DiSCS® automatically regulates the amount of water spray applied relative to vehicle ground speed or distance traveled. This system also provides water pump system protection against operator-induced sudden starts and stops, low water level and overheating due to extended water pump operation. Standard on MAC 7,8,9 and 10 models.

Check out our DiSCS® digital spray control system in action.

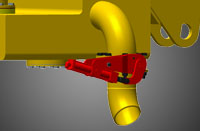

Mega tanks pin directly to the rear pivot mounts of the truck chassis. Line boring the rear pivot mounts ensures accurate direct pin installation of the tank. Mega tanks do not require welding to the frame. New pivot pins and shims are supplied with the tank.

Mega tanks pin directly to the rear pivot mounts of the truck chassis. Line boring the rear pivot mounts ensures accurate direct pin installation of the tank. Mega tanks do not require welding to the frame. New pivot pins and shims are supplied with the tank.

Mega tanks are abrasive blasted prior to application of anti-corrosive primer. The exterior top coat is color matched to the current manufacturers color.

Mega tanks are abrasive blasted prior to application of anti-corrosive primer. The exterior top coat is color matched to the current manufacturers color.

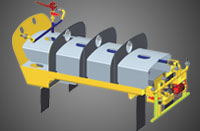

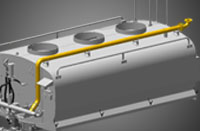

Waterways feeding front spray and appliances are external to the tank.

Waterways feeding front spray and appliances are external to the tank.

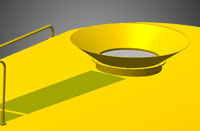

The standard fill port includes a bolt-in safety grate. For safer access to the fill port, an anti-skid walkway is provided. The walkway extends from the access ladder on the front bulkhead to the fill port.

The standard fill port includes a bolt-in safety grate. For safer access to the fill port, an anti-skid walkway is provided. The walkway extends from the access ladder on the front bulkhead to the fill port.

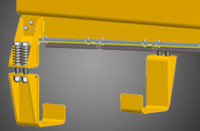

The truck chassis is allowed to flex beneath the spring type front mounting tie downs. No welding is required to install these mounts.

The truck chassis is allowed to flex beneath the spring type front mounting tie downs. No welding is required to install these mounts.

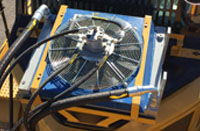

Mega includes a hydraulic oil cooler on most equipment to prevent overheating during extended water pump operation which reduces the risk of hydraulic system failure.

Mega includes a hydraulic oil cooler on most equipment to prevent overheating during extended water pump operation which reduces the risk of hydraulic system failure.

Check out our Hydraulic Integration Video featuring the Hydraulic Oil Cooler.

The Mega hydraulic spray system with intermittent spray provides independent control of all spray nozzles and valving with the dependability of hydraulic actuation. The solenoid control module is mounted inside a weatherproof steel housing mounted on the front bulkhead of the tank.

The Mega hydraulic spray system with intermittent spray provides independent control of all spray nozzles and valving with the dependability of hydraulic actuation. The solenoid control module is mounted inside a weatherproof steel housing mounted on the front bulkhead of the tank.

Internal piping supplies water to the water cannon. External piping feeds other water distribution functions.

Internal piping supplies water to the water cannon. External piping feeds other water distribution functions.

All clearance, stop, and tail lights on Mega tanks are LED for long life and low maintenance. Two work lights are mounted on the rear bulkhead of the tank beneath water shedders. The lights are controlled by switches on the cab control.

All clearance, stop, and tail lights on Mega tanks are LED for long life and low maintenance. Two work lights are mounted on the rear bulkhead of the tank beneath water shedders. The lights are controlled by switches on the cab control.

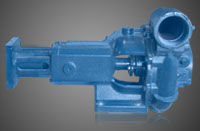

The Mega M3 series heavy-duty water pump features a direct bolt-on hydraulic motor mount and steel splined coupling to simplify drive motor connection. Heavy-duty shaft and dual bearing design provide long life and high water output for superior spray pattern and water cannon performance.

The Mega M3 series heavy-duty water pump features a direct bolt-on hydraulic motor mount and steel splined coupling to simplify drive motor connection. Heavy-duty shaft and dual bearing design provide long life and high water output for superior spray pattern and water cannon performance.

The Mega M4 series high performance water pump features direct bolt-on hydraulic motor mount and steel splined coupling to simplify drive motor connection. The M4 pumps are available in standard cast iron, corrosion-resistant models with stainless steel waterways, and fully stainless steel.

The Mega M4 series high performance water pump features direct bolt-on hydraulic motor mount and steel splined coupling to simplify drive motor connection. The M4 pumps are available in standard cast iron, corrosion-resistant models with stainless steel waterways, and fully stainless steel.

Mud flaps fore and aft of rear drive tires are standard equipment on all Mega tanks.

Mud flaps fore and aft of rear drive tires are standard equipment on all Mega tanks.

Mega protects your investment by providing a one-year warranty against defects in materials and workmanship. Extended warranties are available for purchase. Visit our Warranty Page for more information.

Mega protects your investment by providing a one-year warranty against defects in materials and workmanship. Extended warranties are available for purchase. Visit our Warranty Page for more information.

The rear spray bar is designed to fully utilize the capability of the water pump. The standard rear spray bar is constructed of carbon steel pipe. Optional stainless steel spray bars and spray heads are available as well as swivel couplings. See our optional features.

The rear spray bar is designed to fully utilize the capability of the water pump. The standard rear spray bar is constructed of carbon steel pipe. Optional stainless steel spray bars and spray heads are available as well as swivel couplings. See our optional features.

Mega water tanks include a complete set of technical manuals detailing installation, operation, maintenance, inspection and replacement parts. Additional manuals are available for purchase. Visit our Technical Manuals Page for more information.

Mega water tanks include a complete set of technical manuals detailing installation, operation, maintenance, inspection and replacement parts. Additional manuals are available for purchase. Visit our Technical Manuals Page for more information.

There are two water level indicators, one on the DiSCS® cab control keypad, and the other on the solenoid control module mounted on the tank for easy viewing while filling.

There are two water level indicators, one on the DiSCS® cab control keypad, and the other on the solenoid control module mounted on the tank for easy viewing while filling.

Your standard MAC tank can be configured with these optional features. Availability and specifications may vary by model. For additional information, contact our Mega Sales Team.

Additional sets of manuals are available for purchase. Mega water tanks include a complete set of technical manuals detailing installation, operation, maintenance, inspection and replacement parts. Visit our Technical Manuals Page for more information.

Additional sets of manuals are available for purchase. Mega water tanks include a complete set of technical manuals detailing installation, operation, maintenance, inspection and replacement parts. Visit our Technical Manuals Page for more information.

Remote control hydraulic fan or fog stream nozzles allow adjustable stream patterns for use with Mega water cannons.

Remote control hydraulic fan or fog stream nozzles allow adjustable stream patterns for use with Mega water cannons.

The anti-siphon fill pipe is used with any pressurized water source. It is specifically designed to accommodate municipal water systems and fire hydrants requiring an air gap to prevent water siphoning back into the supply.

The anti-siphon fill pipe is used with any pressurized water source. It is specifically designed to accommodate municipal water systems and fire hydrants requiring an air gap to prevent water siphoning back into the supply.

An extension cable to relocate your camera from the truck to the water tank.

An extension cable to relocate your camera from the truck to the water tank.

The conical fill port allows for easier positioning of the water fill source over the main fill port of the tank.

The conical fill port allows for easier positioning of the water fill source over the main fill port of the tank.

The Corrosion Resistant package protects against tank and component corrosion caused by the harsh waters often found in mining, construction, and landfill environments. Protecting your tank against corrosion adds longevity and dependability to your tank and spray system. The package includes:

The Corrosion Resistant package protects against tank and component corrosion caused by the harsh waters often found in mining, construction, and landfill environments. Protecting your tank against corrosion adds longevity and dependability to your tank and spray system. The package includes:

Mega DiSCS®provides precise application of water spray using CAN bus and logic control technology to operate the spray control system. DiSCS® provides control of all water distribution systems. GPS sensing within DiSCS® automatically regulates the amount of water spray applied relative to vehicle ground speed or distance traveled. This system also provides water pump system protection against operator-induced sudden starts and stops, low water level and overheating due to extended water pump operation.

Mega DiSCS®provides precise application of water spray using CAN bus and logic control technology to operate the spray control system. DiSCS® provides control of all water distribution systems. GPS sensing within DiSCS® automatically regulates the amount of water spray applied relative to vehicle ground speed or distance traveled. This system also provides water pump system protection against operator-induced sudden starts and stops, low water level and overheating due to extended water pump operation.

Check out our DiSCS® digital spray control system in action.

The quick dump drain valve option is a large drain located at the bottom rear of the tank. This option is available with manual or hydraulic remote actuation.

The quick dump drain valve option is a large drain located at the bottom rear of the tank. This option is available with manual or hydraulic remote actuation.

Mega offers two hydraulically-actuated dump bars. Mega's pressurized dump bar sprays penetrating jets of water directly onto the ground. The gravity dump bar is fed directly from the bottom of the water tank and may be used with the water pump turned off to reduce water flow and pressure.

Mega offers two hydraulically-actuated dump bars. Mega's pressurized dump bar sprays penetrating jets of water directly onto the ground. The gravity dump bar is fed directly from the bottom of the water tank and may be used with the water pump turned off to reduce water flow and pressure.

Mega offers complete factory installation for articulated truck tanks for both customer-supplied and Mega-provided tractors. Factory installation includes complete testing prior to delivery.

Mega offers complete factory installation for articulated truck tanks for both customer-supplied and Mega-provided tractors. Factory installation includes complete testing prior to delivery.

Multiple fall protection, D-ring style tie-off points are welded to the top of tank.

Multiple fall protection, D-ring style tie-off points are welded to the top of tank.

The Mega foam agent tank is mounted externally on the top of the water tank. The foam agent tank size varies by model. Mega’s foam agent fire suppression system can be ordered as an option on a new Mega water tank or as a retro kit for installation on an existing water tank.

The Mega foam agent tank is mounted externally on the top of the water tank. The foam agent tank size varies by model. Mega’s foam agent fire suppression system can be ordered as an option on a new Mega water tank or as a retro kit for installation on an existing water tank.

The front bumper spray is commonly used to “sweep” a surface with high pressure fans of water. Spray heads are mounted to spray from both sides of the tractor. The spray heads are fully adjustable for vertical and horizontal directions. The location of the spray bar allows the cab hood to fully tilt and open for engine service. Front bumper spray may restrict cab access. Note: This item is available by special request.

The front bumper spray is commonly used to “sweep” a surface with high pressure fans of water. Spray heads are mounted to spray from both sides of the tractor. The spray heads are fully adjustable for vertical and horizontal directions. The location of the spray bar allows the cab hood to fully tilt and open for engine service. Front bumper spray may restrict cab access. Note: This item is available by special request.

Hose reels installed on Mega tanks include a high quality water hose and an adjustable fog to stream nozzle. Hose reels come in various sizes and are available with manual, spring, or hydraulic rewind. Sizes vary by model.

Hose reels installed on Mega tanks include a high quality water hose and an adjustable fog to stream nozzle. Hose reels come in various sizes and are available with manual, spring, or hydraulic rewind. Sizes vary by model.

Mega tanks are abrasive blasted prior to the application of the interior coating. The epoxy lining is well suited for harsh, acidic, alkaline, and salty waters. Urethane lining is very effective in normal to salty waters. Coating data sheet and MSDS available upon request.

Mega tanks are abrasive blasted prior to the application of the interior coating. The epoxy lining is well suited for harsh, acidic, alkaline, and salty waters. Urethane lining is very effective in normal to salty waters. Coating data sheet and MSDS available upon request.

Magnesium anodes are placed in each tank compartment to reduce corrosion of the tank interior.

Magnesium anodes are placed in each tank compartment to reduce corrosion of the tank interior.

Check out how easy our anodes are to replace!

The Mega Product Support team offers on-site technical assistance, service advice and training to facilitate installation and reduce field assembly and component repair time.

The Mega Product Support team offers on-site technical assistance, service advice and training to facilitate installation and reduce field assembly and component repair time.

Quick change component packages provide specific operation-critical parts for the Mega water tank spray system. Stocking critical parts reduces downtime by eliminating delays related to acquiring replacement parts. QCCP kits are designed specifically for each tank configuration.

Quick change component packages provide specific operation-critical parts for the Mega water tank spray system. Stocking critical parts reduces downtime by eliminating delays related to acquiring replacement parts. QCCP kits are designed specifically for each tank configuration.

The Mega stainless steel hydraulic spray head valve is engineered for use in the most severe environments. The stainless steel hydraulic spray head valve is interchangeable with the Mega aluminum hydraulic spray head valve. Mega hydraulic spray head valve are actuated by a stainless steel, double-acting hydraulic cylinder.

The Mega stainless steel hydraulic spray head valve is engineered for use in the most severe environments. The stainless steel hydraulic spray head valve is interchangeable with the Mega aluminum hydraulic spray head valve. Mega hydraulic spray head valve are actuated by a stainless steel, double-acting hydraulic cylinder.

Suction loading provides tanks with self-loading ability via the discharge pump priming reservoir or a separate, self-priming water pump. Suction loading is used to fill the tank from a natural or man-made reservoir. Discharge pump configurations include an auxiliary manual priming pump, and require customer-provided suction hose. Self-priming pump configurations include storage tubes and hose.

Suction loading provides tanks with self-loading ability via the discharge pump priming reservoir or a separate, self-priming water pump. Suction loading is used to fill the tank from a natural or man-made reservoir. Discharge pump configurations include an auxiliary manual priming pump, and require customer-provided suction hose. Self-priming pump configurations include storage tubes and hose.

Optional swivel couplings allow for vertical spray direction adjustment. Each spray head rotates horizontally to adjust water spray fan direction.

Optional swivel couplings allow for vertical spray direction adjustment. Each spray head rotates horizontally to adjust water spray fan direction.

Two spray head valves are mounted on the front quadrant of the tank for spraying vertical fans of water.

Two spray head valves are mounted on the front quadrant of the tank for spraying vertical fans of water.

Mega water cannons are designed and built to perform in the most severe environments of mining and construction. Our water cannons are ideal for fire suppression, high pressure equipment washing, and applications requiring long-distance or adjustable spray patterns.

Mega water cannons are designed and built to perform in the most severe environments of mining and construction. Our water cannons are ideal for fire suppression, high pressure equipment washing, and applications requiring long-distance or adjustable spray patterns.